RFID in Revolutionizing Asset Tracking Across Industries

A recent article highlighting the 25 Technologies that have changed the world lists the usual blockbuster inventions, such as the Apple iPhone, Wi-Fi, AI, facial recognition, drones, DNA testing, social platforms, quantum computing and bitcoin. However, not all of these world-changing technologies are so famous. Who knew that Radio Frequency Identification (RFID) is a world-changing technology?

A recent article highlighting the 25 Technologies that have changed the world lists the usual blockbuster inventions, such as the Apple iPhone, Wi-Fi, AI, facial recognition, drones, DNA testing, social platforms, quantum computing and bitcoin. However, not all of these world-changing technologies are so famous.

Who knew that Radio Frequency Identification (RFID) is a world-changing technology?

RFID is now a key technology across a growing number of industries. RFID uses electromagnetic fields to automatically identify and track objects. This simple technology has just two components: RFID tags (transponders) and RFID readers. The tags contain data, which are accessed by the reader via radio waves. Unlike barcodes, RFID tags do not require line-of-sight to be scanned, making them more versatile and efficient for asset tracking.

The read range of an RFID tag refers to the distance from which the tag can be detected by the RFID reader. There are two basic types of RFID tags – Passive and active. Passive tags do not require batteries and get their power from the electromagnetic waves of the RFID reader.

Read how Amazon is using RFID for its new Just Walk Out technology where customers can grab clothes, hats, shoes, and more—and simply walk out of the store through an exit gate (even while wearing their purchases) by tapping their credit or debit card, or hovering their palm over an Amazon One palm recognition device. No more checkout lines for clothes!

RFID systems are simple, adaptable, and easily connect with a range of hardware and software. That’s why RFID is a world-changing technology.

Read the article from the National Institutes of Health entitled “Radio Frequency Identification (RFID) in health care: where are we? A scoping review”

Read an article by Atlas RFID store about the many ways that RFID is used to identify and manage wine, beer, and spirits.

RFID is being used to identify, verify and connect to utilities - from buried gas lines to fiber to hydrants. Learn more.

Retail

Now that self-checkout is everywhere, we all understand the frustration of scanning bar codes. Fortunately, many retailers are moving to RFID-enabled shopping carts and baskets to improve the customer experience. Instead of struggling to find a code and scan it, the customer just drops the item in the cart/basket, and it’s scanned. Additionally, RFID-enabled shelves can provide in-depth information on any product via the NFC capability on most cell phones.[1]Logistics

Cargo tracking is essential in the logistics industry. Because RFID tags are available in many forms, they can be affixed to nearly everything, from individual packages to shipping containers, vehicles, train cars and so on. Shipments can be tracked in real-time from origin to destination from a distance. Any interruptions can be quickly detected and resolved, saving time and money.Healthcare

If you’ve been in a hospital, it’s hard to miss the medical equipment wheeled into every available space. Hospitals are continually challenged to efficiently use this equipment, not only because of cost, but also because of regulatory requirements. RFID is making a huge difference in keeping track of every device, as well as it’s maintenance history and what specific device has been used on each patient. In many facilities today, patient wrist bands are also RFID-enabled to ensure the patient is accurately tracked as they move through the treatment process.Manufacturing

Tracking inventory parts and manufactured assemblies has always been a challenge in manufacturing. Bar codes were initially used to address the issue, but the requirement for a line of sight reduces efficiency. RFID delivers efficient inventory tracking without visible markers, enabling product monitoring throughout the manufacturing process.Hospitality

Years ago, hotels replaced locks and keys with RFID-enabled cards. Today, the use of RFID is not limited to access control – now, RFID is used for inventory control as well. RFID tags on hotel and restaurant supplies provide inventory control, while tags on amenities such as hair dryers, robes, and so on, help prevent loss.Agriculture

RFID tags are used for tracking and monitoring livestock as well as for monitoring wildlife.

RFID tags on livestock have become commonplace. Tags are placed on animals soon after birth, tracking their passage from farm to stockyard to supermarket. Besides providing food traceability that is so important for health, RFID helps to manage disease within herds. RFID helps to collect data on individual animals’ behavior and health. That means that outbreaks can be quickly detected and treated as they occur.

In wildlife research, RFID tags are placed on managed endangered species populations, migratory birds, or large mammals. These tags enable researchers to identify individual animals, track their movements, and collect a broad range of data.In both livestock farming and wildlife conservation, asset tracking helps prevent theft and poaching. RFID tags can trigger alarms if an animal leaves a designated area or if an unauthorized person attempts to move an animal.[2]

Museums

Recent headlines highlighting the loss of irreplaceable items at prominent museums highlight the challenge curators face as they must receive, catalogue, store, and display millions of artifacts. A new study showed how RFID can help paleontologists keep track of dinosaur bones from dig to display.RFID can help the visitor experience. When issued an RFID-enabled badge, an audio presentation will be triggered by the proximity to the displayed artwork, providing a wealth of information about the work, it’s creator and history. The data generated from each visitor’s visit can be analyzed to gain insight into visitor traffic patterns, exhibit popularity and even the impact of different lighting and environmental conditions over time. This helps the curator better manage the museum.In art museums, priceless works can be tagged with a discreet RFID label that will trigger alarms if the piece is moved without authorization.

Wine

RFID technology helps vineyards maintain accurate inventory information for real-time tracking of product movements, minimizing the risk of over- or under-stock. RFID tags can monitor temperature and humidity throughout the supply chain to maintain product quality and safety. At the retail location, Point of Sale Inventory Replenishment can automatically update the inventory, ensuring that customers can always get their favorite vintage.Infrastructure

RFID is particularly suited to the management of any type of infrastructure asset, from utility poles to buried valves. A simple RFID tag delivers the location, identity and owner of any asset anywhere. If used widely, RFID would enable cities, airports and utilities to better manage excavation and construction by providing on-site verification of any type of buried asset. The cost of unintentional utility strikes costs the U.S. more than $30 billion annually, according to the Common Ground Alliance. This expense is an unnecessary burden on economic development with no upside.

The RFID market is growing rapidly

The global RFID market is expected to grow from USD 15.8 billion in 2023 to USD 40.9 billion in 2032 at a CAGR of 11.1% during this time. As more and more industries leverage the power of RFID, the applications of RFID will expand. The convergence of RFID, IoT, Artificial Intelligence and Machine Learning will deliver transformative technologies to all sectors, making sense of data and providing a new depth and breadth of understanding.

Berntsen is here to help customers take advantage of this technology with its InfraMarker RFID solution. InfraMarker combines the power of GIS with RFID to deliver accurate, verified asset identification any time and anywhere. See how InfraMarker can change your world.

RFID - resilient and adaptable

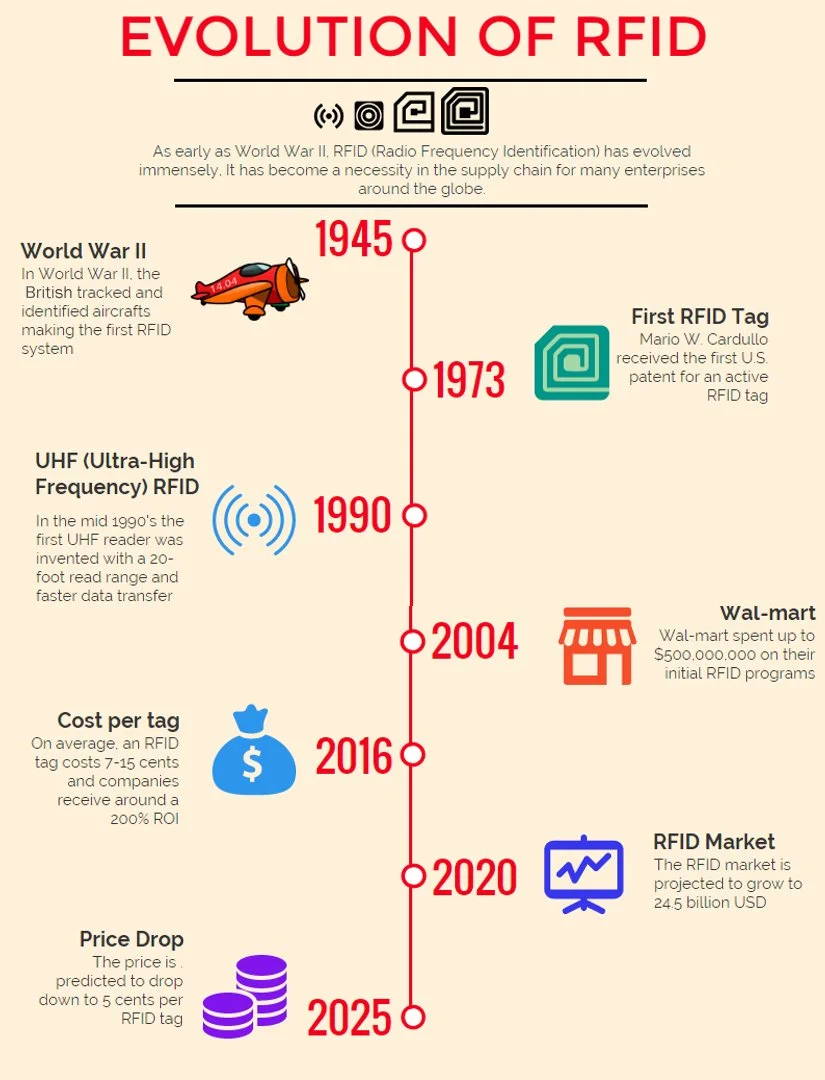

Radio Frequency Identification (RFID) has been around for a long time. The precursor technology to RFID was originally developed as a musical instrument by the Russian physicist Leon Theremin, patented in 1928. The Theremin produces music by manipulation of electromagnetic fields around two antennae to produce sound.

Radio Frequency Identification (RFID) has been around for a long time. The precursor technology to RFID was originally developed as a musical instrument by the Russian physicist Leon Theremin, patented in 1928. The Theremin produces music by manipulation of electromagnetic fields around two antennae to produce sound.

Key technology during WWII

During WWII, the British used radio frequency identification to detect which incoming aircraft were friend or foe. They placed a radio transmitter on each plane. When it received signals from radar stations on the ground, it began broadcasting a signal back that identified the aircraft as friendly. This is the key function of RFID. A signal is sent to a transponder, which wakes up and either reflects back a signal (passive system) or broadcasts a signal (active system).[1]

Manipulation of radio frequency also played a role in protecting Allied war ships during WWII. In the early 1940s, the Allies were gearing up for a war that would determine the history of the world and were using all available technologies to gain an edge. One of the new weapons was a radio-controlled torpedo that could enhance the range and accuracy of the weapon. A Hollywood actress with a genius-level IQ and an interest in technology heard about this technology. Hedy Lamarr was aware that these torpedoes could easily be jammed by the enemy, rendering them ineffective. Radio jamming is the intentional transmission of radio signals on the same frequency as another communication channel, with the goal of disrupting or interfering with that communication. She believed that if the frequency used to control the torpedo was constantly changing, it would be much more difficult for the enemy to jam the signal and prevent the torpedo from reaching its target.

So she set to work with a friend, Georg Antheil, a composer with an interest in machinery and developed “frequency-hopping” to ensure the radio signals couldn’t be jammed. In frequency hopping, the transmitter and receiver rapidly switch between different channels in a predetermined sequence. This sequence is known to both the transmitter and the receiver, and it is usually designed to cover a wide frequency range to increase the likelihood of finding a clear channel. Lamarr and Antheil received a patent for this technology and donated it to the US Navy, never getting any money from it.[2]

Later, radio frequency technology was used by the Soviets to produce a covert listening device. In 1945 the Soviet Union presented a hand-carved ceremonial seal of the USA to the US ambassador, Averell Harriman. Unfortunately, this wasn’t just a gift, it was a new kind of listening device. Hidden within the artwork was an antenna activated by radio waves that were directed at the US embassy by the Soviets. This served as a microphone and broadcast private conversations back to the Soviets. It wasn’t initially found by embassy staff because the device had no batteries or wires to detect. For seven years, private conversations in Harriman’s study were unknowingly broadcast to the Soviets.[3]

Computers & RFID - a powerful combination

By 1973, memory was added to the radio frequency technology. It consisted of a transponder with 16 bit memory for use as a toll device for the New York Port Authority. The basic patent covers the use of radio frequency (RF), sound and light as transmission carriers.[4] The commercial uses of the technology for passive, contactless identification were apparent, and rapid development and commercialization began in earnest.

Graph derived from a market report by MarketsandMarkets, titled RFID Market Size, Share, Statistics and Industry Growth Analysis Report by Offering (Tags, Readers, Software & Services, Tag Type (Active, Passive), Wafer Size, Frequency (Low Frequency, High Frequency, Ultra-high Frequency), Form Factor, Material, Application and Region - Global Forecast to 2032.

Today, the market for RFID is exploding. According to a comprehensive report by MarketsandMarkets, the global RFID market size is projected to reach USD 40.9 billion by 2032 from USD 15.8 billion in 2023; it is expected to grow at a CAGR of 11.1% from 2023 to 2032. This growth is indicative of the increasing adoption of RFID technology as a powerful enabler of connectivity and data visibility.[5]

Now, RFID is used across all sectors of industry, from agriculture to manufacturing, education, health care, retail, supply chain management – anywhere the instantaneous, contactless and precise identification and tracking of any item is needed. Its simplicity and versatility means that it can be combined with other technologies to deliver location-based data immediately. For example, RFID is being used with artificial intelligence technologies to reliably predict patient falls and detect human activities. It can help provide insight into transport conditions for perishable products, and support sustainability by helping to identify and reduce waste in supply chain management.

RFID & GIS

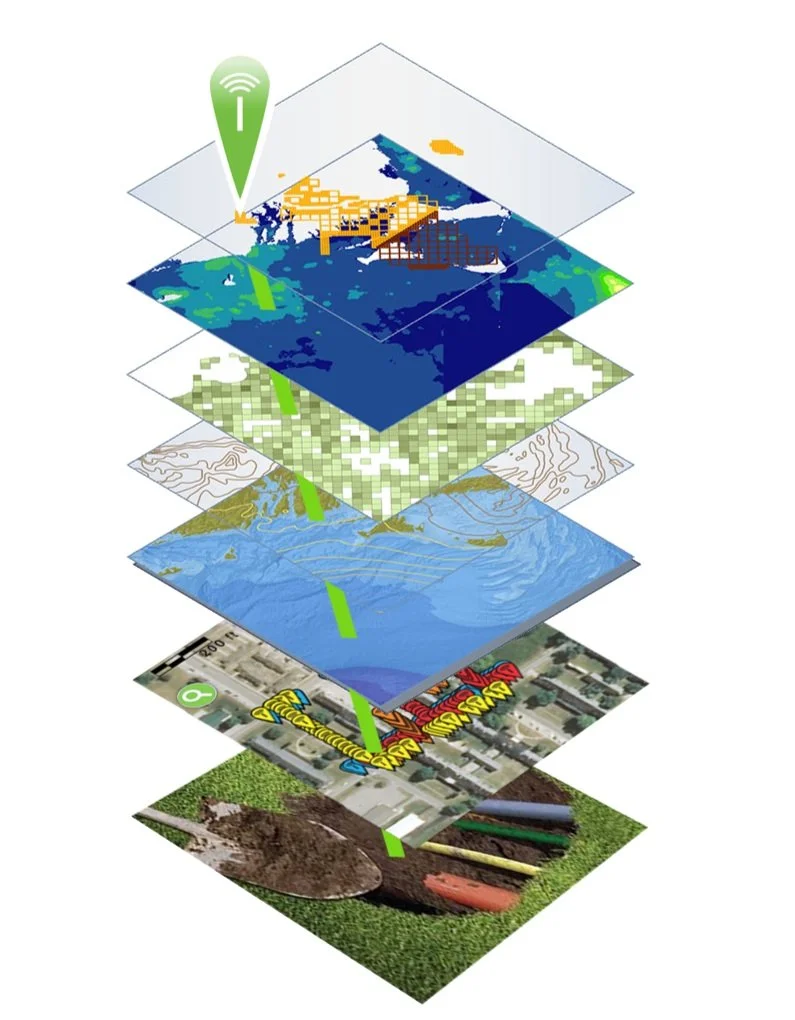

RFID is now being tapped to help manage all types of assets in combination with Geographic Information Systems (GIS). When used together, GIS and RFID deliver accurate, verified information about any type of asset – even below-ground. This information is incredibly useful when re-locating buried assets before excavation. RFID means that field workers can know exactly what’s below simply by scanning the buried RFID asset tag through InfraMarker RFID apps that display that specific asset’s data.

Berntsen’s partnership with Esri gives users of the popular Survey123 and Field Maps data collection apps the opportunity incorporate the benefits of InfraMarker RFID into their asset tracking. Berntsen’s partnership with HID means that its RFID tags and readers come in a wide variety of configurations, from rugged underground magnetized markers to ultra-thin labels designed for accurate and reliable inventory control.

RFID Journal Live Conference

In a few days, experts will be unveiling the future by sharing the latest applications, enhancements, and new advancements RFID technology. The Conference brings together users, developers, and exhibitors from all over the world at the MGM Grand in Las Vegas from April 9-11. Mike Klonsinski, president of Berntsen will be presenting a session about a unique use of our versatile InfraMarker RFID technology:

Dinosaur Dig to Display: Transforming Asset Management in the Field

Tuesday, April 9 | 1:50 pm to 2:30 pm Room No: 357

Session Description

When 347 fossil specimens were discovered on Standing Rock Sioux lands in South Dakota, the Earth Science Foundation (ESF) turned to technology to advance their fossil recovery operation. The ESF team led the excavation, documentation and handling of paleontological specimens and needed an innovative solution. In response to that need, InfraMarker RFID, HID and Esri ArcGIS joined forces to deliver best asset management practices.

Learn how the solution uses the combined technology to improve field workflows, tracks, and traces bones from field to display, and aids dashboards for operations managers and remote stakeholders.

RFID continues to be a core technology for our future, and the RFID Conference highlights how this simple technology is making our lives better. We look forward to seeing you there!

Damage prevention saves lives and money

April is recognized by Congress and most Governors across the U.S. as National Safe Digging Month as shovels (and backhoes) hit the ground for a busy season. It’s well known that excavation is a dangerous business. Excavation strikes on public utility lines lead to more than 2,000 injuries and 400 deaths each year. The Common Ground Alliance (CGA) states that accidental utility strikes cost the U.S. at least $30 billion annually, based on self-reported data by stakeholders and state 811 call centers. And it looks like things are getting worse, not better.

April is recognized by Congress and most Governors across the U.S. as National Safe Digging Month as shovels (and backhoes) hit the ground for a busy season. It’s well known that excavation is a dangerous business. Excavation strikes on public utility lines lead to more than 2,000 injuries and 400 deaths each year[1]. The Common Ground Alliance (CGA) states that accidental utility strikes cost the U.S. at least $30 billion annually, based on self-reported data by stakeholders and state 811 call centers. And it looks like things are getting worse, not better.

Trends indicate more, not fewer damages

The CGA’s most recent data show that the number of incidents is increasing. A three-year trend (2020-2022) points to a 9.34 percent increase in utility strikes. With more than a half-trillion dollars allocated to new infrastructure in the U.S. over five years, it’s essential all organizations involved in excavation prioritize ways to reverse this dangerous and costly trend.

Many organizations are involved in excavation - professional excavators, landscapers, contractors, utilities, local, state and federal agencies, site owners and others. A single excavation site has dozens of contractors working in the same space at the same time. Surprisingly, there are few national guidelines for safe excavation processes, except for the one-call system established in 1994. This law directed states to have a phone number to call for underground locating. In most states, that number or link is 811.

Calling (or clicking on) 811 for locating services before excavation greatly reduces the risk of utility strikes. Unfortunately, nearly 25% of all reported utility damages result from NOT calling 811, as this chart from CGA shows.

An industry group, the Infrastructure Protection Coalition, is working to standardize the use of 811 by all parties involved in excavation. Their report states that

“A handful of states account for more than 20 percent of the national waste [related to 811], a combined $13 billion, because of 811 policies that lack teeth and, in some cases, do not require mandatory reporting of damage to utility lines. . . [The analysis shows that] these costs and the increased risk to public safety could be substantially reduced if states with the worst records adopted more effective practices and procedures already in use in other parts of the country.”

811 Emergency, National Report, 6/15/2022, Infrastructure Protection Coalition

Focus on policy

It appears that now is the time to call for a national approach to damage prevention. The CGA has just announced the formation of the Damage Prevention Action Center, an entity made up of industry leaders to advocate for data-driven legislative and regulatory policies and industry practices that protect our critical underground utility infrastructure and those who work and live near these important assets. It’s vital that legislation be based on data and best practices, and this group aims to ensure fact-based regulation.

Ambitious goals – achievable with technology

The CGA has set an ambitious goal of reducing damages by 50% over the next five years. Consistent and widespread use of 811 is key, but to reach that goal, other priority action areas must be leveraged. “For facility owners, GIS-based mapping of assets and communication are urgently needed to improve locating timelines and accuracy.”

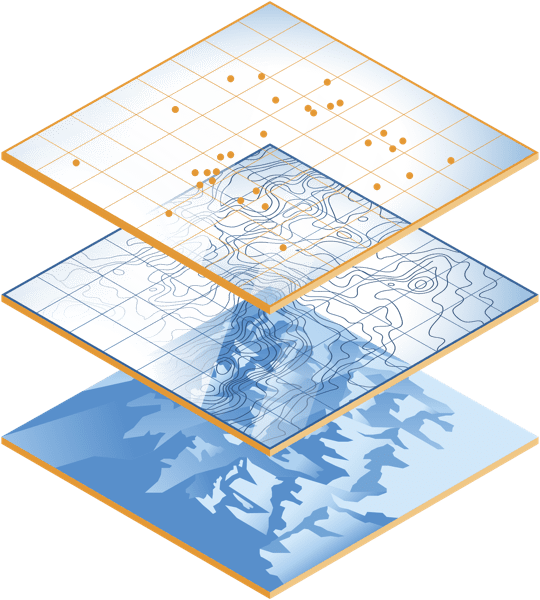

Geographic Information Systems (GIS) are already used extensively by municipalities and utilities across the country. These platforms are ideal for mapping and visualizing underground infrastructure and are already in use by many utilities and municipalities across the country.

Adding processes for mapping underground utilities as they are they are installed (or uncovered by new excavation) can provide highly accurate, shareable maps for every contractor on a construction site. These efforts are already underway. For example, Esri, a global leader in GIS, delivers capabilities designed to make the visualization, identification, mapping and management of underground utilities accessible for all stakeholders. Its ArcGIS platform is ideal for generating accurate visual depictions of location and other data in layers. This platform uses data from a wide range of sources, including field operations. Field workers use cell phones or tablets to collect data in real time as they install underground infrastructure.

To ensure location data is absolutely accurate for future excavations, Esri offers the InfraMarker RFID app that integrates with its Field Maps or Survey123 field data collection software. As utilities are buried (or uncovered during excavation), RFID tags are placed on or near critical points, such as fiber junctions, valves, places where multiple assets converge and so on. Essential data about the asset, its owner and location data are written to each tag for future on site location and verification. This data is linked to ArcGIS via the InfraMarker/data collection apps, providing verified location data of the buried utility while also linking it to critical information about the asset, including video, schematics, maintenance and other data.

What this means is that in the future, when excavation on the same site is required, the exact location, owner and nature of underground assets can be verified on the spot. Buried RFID tags can be read before ground is broken from above using RFID readers connected to the Esri/InfraMarker data collection apps. Above ground RFID tags can also be read with a cell phone held close proximity to the tag.

The data owner can choose to share selected data with other contractors, preventing damage to their critical underground facilities during excavation.

Accurately mapping of underground assets is key to preventing damage. If used consistently, GIS and RFID deliver in-field location verification and identification data that streamline buried asset locating – preventing costly utility strikes and construction delays.

See it for yourself

Berntsen International supports CGA’s mission and will be showing InfraMarker RFID at the upcoming CGA Conference and Expo April 14-18 at the Broadmoor in Colorado Springs, Colorado in booth 322. We look forward to seeing you there!

References:

NP Case Study Minnesota Utilities Mapping (commongroundalliance.com)

https://www.linkedin.com/pulse/striking-balance-unearthing-facts-solutions-utility-line-machuca/

https://www.theutilityexpo.com/news/digging-safely-preventing-underground-utility-stri

https://www.amprobe.com/consequences-of-striking-underground-infrastructure/

Federal agencies get the job done

For more than 50 years, Berntsen has worked alongside federal agencies to provide useful and quality products. From monuments that can be set in wetlands to RFID markers that integrate with Geographic Information Systems (GIS), federal agencies rely on Berntsen to deliver quality products that help them fulfill their missions.

For more than 50 years, Berntsen has worked alongside federal agencies to provide useful and quality products. From monuments that can be set in wetlands to RFID markers that integrate with Geographic Information Systems (GIS), federal agencies rely on Berntsen to deliver quality products that help them fulfill their missions.

See us at booth 830 at the Esri FedGIS Conference on February 13-14, 2024

In partnership with Esri, Berntsen is looking forward to demonstrating how InfraMarker RFID can help federal agencies better manage their diverse assets at the upcoming Esri FedGIS Conference. Stop by booth 830 to see how the InfraMarker RFID App for ArcGIS can help you identify, verify and update data for any type of asset in the field with a simple scan. Anything (even underground) that can be marked with an RFID tag can connect to ArcGIS for accurate identification and management. We look forward to seeing you there!

Federal Agencies – partnering with industry to get the job done

Federal agencies are key to maintaining a safe, stable, and thriving nation. From the Department of Defense, that protects Americans at home and abroad, to the Department of Interior that manages America’s vast public lands, to NASA, tasked with exploring the unknown for all the citizens of our planet, federal agencies provide the structure and do the work that makes our country thrive.

One thing these agencies have in common is that they manage many types of assets across vast spaces. From ensuring that gas pipelines are built and operated safely, to marking out trails in national parks, to building dams, highways and runways, these agencies rely on the private sector for products and technologies that help get more done with fewer resources.

Since the foundation of our country, federal agencies have quietly been getting the job done, ensuring stability and growth. This vital structure didn’t happen overnight, and it’s interesting to see the evolution of how these agencies developed.

Department of Defense (DOD)

The DOD is America's largest government agency, with more than 2,870,235 employees and service members. Tracing its roots back to pre-Revolutionary times, the department has evolved with our nation.

The Army, Navy, and Marine Corps were established in 1775, to support the American Revolution. In 1789, Congress created the War Department, responsible for both the Army and Navy until the founding of a separate Department of the Navy in 1798. After World War II, the War Department was reorganized and by 1949, the command structure was unified, and the Department of Defense was created.

Today, the DOD has four branches (Army, Navy, Air Force, and Coast Guard) with the Marines organized under the Navy, and the new Space Force organized under the Air Force. The branches are made up of 34 agencies, including the National Geospatial-Intelligence Agency; and divisions including the US Army Corps of Engineers. Additionally, two organizations are staffed with uniformed service members but don’t report to the Secretary of Defense. These include the Public Health Service Corps (reporting to the Surgeon General who reports to the Assistant Secretary of Health in the Health and Human Services Department) and the National Oceanic and Atmospheric Administration, (NOAA), reporting to the Secretary of Commerce[1]. Interestingly, the NOAA includes the National Geodetic Survey, our oldest scientific agency. In 1807, President Thomas Jefferson founded the U.S. Coast and Geodetic Survey (as the Survey of the Coast) to provide nautical charts to the maritime community for safe passage into American ports and along our extensive coastline[2].

Berntsen has been serving the DOD for decades. In fact, it was a request from the DOD that sparked a new way of creating survey markers.

The first logo marker in cast aluminum.

Back in the late 1970s, the DOD asked Berntsen if the company could create survey disks for a project in Saudi Arabia. The catch was that the disks needed to include Arabic text and the country’s coat of arms -- a palm tree and crossed swords. Back then, the lettering on survey disks was created using zinc letters glued to a wooden pattern. No Arabic zinc letters were available, and there was no way to include artwork on a disk without going through an expensive and time-consuming engraving process. Long story short, by adapting paste-up and letterpress printing processes to metalwork, Berntsen created the first survey markers using Arabic lettering and illustrations. Today, our survey markers are used across many federal agencies.

Read the story of the first logo marker in American Surveyor.

The Department of Interior (DOI)

Although the idea of a Department of Interior was originally considered in the very first congress in 1789, but instead created the Department of State. However, after the Louisiana Purchase (In 1803) and the lands acquired in the Mexican-American War (1848), it became clear that the vast lands required direct management, rather than being parceled out to other agencies to manage.

Appalachian Trail Marker for the National Park Service

In 1848, the Secretary of the Treasury Robert J Walker did a comprehensive review of the duties of the agencies under his control and other agencies throughout the federal government. He determined that the General Land Office, along with the Indian Affairs Office (in the War Department), The Patent Office (in the State Department), and the pension offices (in the War and Navy departments), had little in common with their (respective) departments. He suggested that they be moved into a new department and went about drafting a bill to accomplish his objective. On March 3, 1849, the legislation was approved by the Senate, thus creating a cabinet agency known as the Department of the Interior (DOI). Subsequently, Interior functions expanded to include the census, regulation of territorial governments, exploration of the western wilderness, and management of the D.C. jail and water system.

Over time, additional functions have been added to and removed from the DOI’s management. Those added include: the US Geological Survey, 1879; the Bureau of Reclamation, 1902; the Bureau of Mines, 1910; the National Park Service, 1916; the US Fish and Wildlife Service, 1940; and the Bureau of Land Management, 1946.

Responsibilities have been moved to other departments. In 1925, the Patent Office was transferred to the Department of Commerce. In 1930, the Bureau of Pensions was transferred to the Veterans Administration[3].

Nevertheless, the purview of the DOI is massive. For example, one of its entities, the Bureau of Land Management oversees 245 million acres of public lands, manages 30% of the nation’s mineral resources, and contributes $1.2 billion annually in economic contributions, such as solar and wind power and geothermal energy[4].

Navajo Nation bronze cadastral survey marker

Another service, the National Park Service, includes 428 areas covering more than 85 million acres in every state, the District of Columbia, American Samoa, Guam, Puerto Rico, and the Virgin Islands. These areas include national parks, monuments, battlefields, military parks, historical parks, historic sites, lakeshores, seashores, recreation areas, scenic rivers and trails, and the White House[5].

Over the years, Berntsen has supported the DOI by delivering innovative and quality products for decades. From thousands of monuments for the Bureau of Land Management, to custom bronze markers for the Navajo Nation to markers for the National Park Service, to RFID-enabled asset marking, Berntsen has been supporting federal agencies since its inception.

Department of Transportation (DOT)

Brochure for the first lightweight magnetic aluminum alloy monument.

The Department of Transportation is a newer executive agency, created during the Johnson administration in 1967, reporting directly to the President. The agency coordinates funding and manages aviation, rail, highway, public transit, hazardous pipelines and other functions involved in the safe transit of people and goods[6].

A request from the Wisconsin Department of Transportation (WISDOT) triggered the invention that built Berntsen. Back in the early 1970s, Peter Berntsen heard about the need for a lighter, more portable survey monument to be used by WISDOT. As owner of Berntsen Cast products, Peter was in the position to solve the problem. With the help of a metallurgist at the University of Wisconsin, Berntsen developed a corrosion-resistant, aluminum-alloy magnetic monument weighing just 8.5 pounds. This innovative monument (the W-1B) proved to be so durable and popular that it established Berntsen as the leader in marking the infrastructure of the world.

Berntsen – providing the right tools at the right time

Over the years, the DOD, DOI, DOT and their bureaus and services have all relied on Berntsen to fulfill their missions - including the US Forest Service, the US Department of Agriculture, the Bureau of Reclamation, US Fish and Wildlife Service, the US Geological Survey, the National Park Service, NASA, and many more.

Berntsen markers delineate the borders of national parks, and our Carsonite trail markers help citizens safely enjoy scenic trails. Berntsen offers a full toolbox for right-of-way management, from utility posts and decals to metal markers to passive RFID tagging. Our InfraMarker Connected RFID links any type of physical asset to GIS, streamlining the identification, tracking and management of everything from pipelines to dinosaur fossils.

See us at the FedGIS Conference!

In partnership with Esri, Berntsen is looking forward to demonstrating how InfraMarker RFID can help federal agencies better manage their diverse assets at the upcoming Esri FedGIS Conference. Stop by booth 830 to see how the InfraMarker RFID App for ArcGIS can help you identify, verify and update data for any type of asset in the field with a simple scan. Anything (even underground) that can be marked with an RFID tag can connect to ArcGIS for accurate identification and management. We look forward to seeing you there.

Key Trends in 2024

The “Fourth Industrial Revolution” is well underway. Back in 2011, economist Klaus Schwab coined the term to refer to the rapid digitization and accessibility of technologies that spark a global shift in processes – in everything from how we communicate to how businesses and governments are managed.

The “Fourth Industrial Revolution” is well underway. Back in 2011, economist Klaus Schwab coined the term to refer to the rapid digitization and accessibility of technologies that spark a global shift in processes – in everything from how we communicate to how businesses and governments are managed[1].

Drone image by Florian Pircher from Pixabay

More a decade later, this revolution is accelerating, driven by the widespread use of cloud computing, “big data”, virtual reality and artificial intelligence (AI). These “disruptive technologies[2]” are fundamentally changing our lives and how we do our jobs. All industries, including surveying and civil engineering, are leveraging these new technologies to automate tasks, increase precision and generate more useful data.

Integration of 3D Laser Scanning Technology (LiDAR)

3D laser scanning traces back to the early 1960s when researchers experimented with laser technology to measure distances and create 3D representations of objects. The first practical applications of laser scanning emerged in the 1970s, in the field of surveying and topographic mapping. However, 3D laser scanning didn’t become useful until advancements in computing power and data processing capabilities were integrated with portable scanning technology. Today, surveyors can combine 3D scanners with their total stations to measure distances and create accurate three-dimensional representations of the surveyed area. The use of 3D laser scanning enhances data collection speed, accuracy, and enables more comprehensive visualization and analysis[3]. Berntsen offers a line of laser targets designed to work with these advanced systems – enhancing accuracy and ensuring repeatability.Drones

Drones equipped with high-resolution cameras and LiDAR sensors capture imagery and terrain data, allowing surveyors to obtain valuable insights for mapping, topographic surveys, and volumetric calculations. This technology makes it possible to survey inaccessible areas, reducing field time and increasing the efficiency of data collection and processing[3]. Of course, having accurate reference points is key to successful aerial surveying – see how Berntsen’s drone targets can work for you.Building Information Modeling (BIM)

BIM uses a range of technologies to create a digital representation of a structure or infrastructure project, integrating survey data with architectural, engineering, and construction information. Surveyors contribute crucial geospatial data to BIM models, facilitating clash detection, accurate quantity take-offs, and construction coordination. BIM enhances collaboration among project stakeholders, reduces errors, and enhances overall project efficiency[3]. Berntsen helps surveyors ensure BIM data precision with its line of smart targets and reflectors.

Augmented Reality (AR) and Virtual Reality (VR) Applications

Augmented Reality (AR) and Virtual Reality (VR) technologies are finding their way into land surveying practices, offering immersive experiences and enhanced visualization. AR and VR applications enable surveyors to overlay survey data onto the real world or create virtual environments for project planning and simulation. These technologies aid in communication, decision-making, and public engagement, providing stakeholders with a better understanding of the surveyed area and proposed designs[3]. These visualizations are extremely precise when surveying measurements include the use of high-quality prisms that help ensure accuracy – available from Berntsen.Geographic Information Systems (GIS)

Cloud-based Geographic Information Systems provide centralized storage, access, and analysis of map-based survey data. GIS is another technology that was first developed in the 1960s using existing spatial analysis and visualization methods, combined with computing power, to identify and manage land characteristics and use over large areas. Soon the usefulness of a spatially based approach to data visualization and analysis was applied to a vast range of functions. Today, GIS is becoming more and more powerful through the integration of other technologies, including Radio Frequency Identification (RFID) and AI.

Radio Frequency Identification (RFID)

As data visualization gets better and better, it becomes increasingly important to ensure that the data itself is precise. That’s where RFID comes in. RFID literally ties the physical to the digital, authenticating any marked asset at its physical location. An RFID tag, placed on anything anywhere can be instantly read on-site, activating its full data record from the GIS or BIM platform. Today, the combination of GIS and RFID is used to verify and manage a vast array of items – from infrastructure assets to dinosaur bones. Berntsen offers a full range of RFID tags and software that integrate with GIS, BIM and other platforms to provide instant authentication to any asset, anywhere.Artificial Intelligence (AI)

AI is set to bring another wave of change to the way we live. AI is the ability of a machine to display human-like capabilities such as reasoning, learning, planning and creativity. AI enables technical systems to perceive their environment, deal with what they perceive, solve problems and act to achieve a specific goal. The computer receives data - already prepared or gathered through its own sensors such as a camera - processes it and responds. AI systems can adapt their behavior to a certain degree by analyzing the effects of previous actions and working autonomously[4].

Combining AI with geographic information system (GIS) and RFID technology delivers real-world context and authentication to operations.

According to Esri, close observers of AI have noted that as an analytic tool, much of what it accomplishes falls into three main categories in which AI and location intelligence fit seamlessly:

Automate tasks and repeat them quickly at scale. A utility company can use AI and location intelligence, along with drone [and RFID] technology, to examine utility poles and wires, determining where telltale signs suggest repairs are necessary.

Look at past patterns to make predictions. A logistics or manufacturing company can use AI and location intelligence to optimize supply chains, considering such disparate data as weather forecasts, the likelihood of ship and rail traffic backup, and how many left-hand turns there are on driving routes.

Search for patterns hidden in large amounts of data[5].

A key point

In the midst of the Fourth Industrial Revolution, it’s important to remember that there are some things that data, computing and visualization can’t do. Every person exists in the physical world, not as a consumer or data point, but as living, breathing, thinking being.

At Berntsen, we put people first, by caring for our customers, anticipating future needs, and providing personal support, from live webinars to one-on-one meetings. We all want to leave our mark, and Berntsen is here to help.

References:

[3] https://www.pointscan.co.uk/the-evolution-of-3d-laser-scanning/

[5] https://www.esri.com/content/dam/esrisites/en-us/media/ebooks/artificial-intelligence.pdf

Background:

https://www.landform-surveys.co.uk/news/thoughts/ai-surveying/

https://www.linkedin.com/pulse/emerging-trends-land-surveying-practices-primaverse/

GIS Day - Mapping our past with the help of RFID

It’s Geographic Information Systems (GIS) Day! Since 1999 when it was first celebrated as the grand finale to Geography Week, GIS has been quickly put to use by many professions, industries and researchers. Today, GIS is becoming indispensable for paleontology - with the help of RFID.

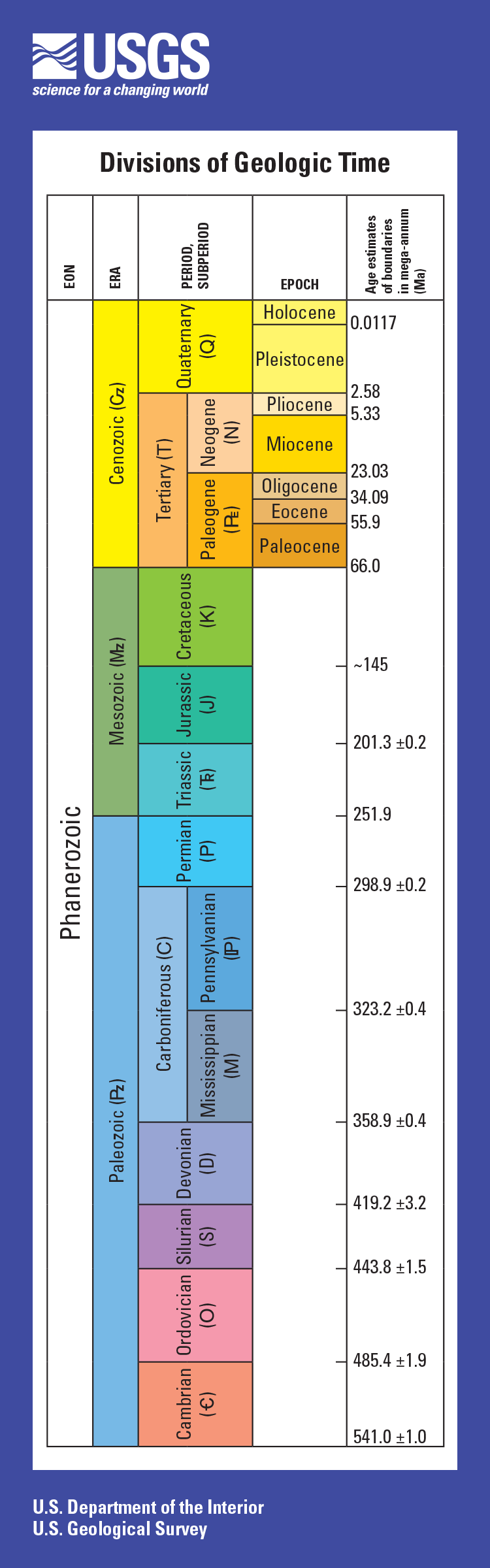

Ages shown for divisions of geologic time are general representations. Ages in mega-annum mean millions of years before present. Box heights are related to how long time periods lasted; different scaling factors are used for the column on the front of the bookmark and for the column on the back, which represents a much longer time period. Map symbols are in parentheses. For more specific age information, see U.S. Geological Survey Fact Sheet 2018–3054 (https://doi.org/10.3133/fs20183054).

It’s Geographic Information Systems (GIS) Day! Since 1999 when it was first celebrated as the grand finale to Geography Week, GIS has been quickly put to use by many professions, industries and researchers. Today, GIS is becoming indispensable for paleontology - with the help of RFID.

The Age of Dinosaurs

According to the United States Geological Survey (USGS), the 'Age of Dinosaurs' (the Mesozoic Era) included three consecutive geologic time periods (the Triassic, Jurassic, and Cretaceous Periods). Different dinosaur species lived during each of these three periods. For example, the Jurassic dinosaur Stegosaurus had already been extinct for approximately 80 million years before the appearance of the Cretaceous dinosaur Tyrannosaurus. In fact, the time separating Stegosaurus and Tyrannosaurus is greater than the time separating Tyrannosaurus and you.

At the beginning of dinosaur history (the Triassic Period), there was one supercontinent on Earth called Pangea. Many dinosaur types were spread across it. However, as Pangea broke apart, dinosaurs became scattered across the globe on separate continents, and new types of dinosaurs evolved separately in each geographic area (1).

When were fossils recognized as ancient dinosaur remains?

Fossils have probably been found throughout human history, despite not being recognized for what they are. Discoveries of their bones were often attributed to giant versions of known animals, or even giant people. Perhaps dinosaur bones inspired the stories of griffins, giants, and dragons.

Fossils of dinosaurs, described by a Chinese historian in the 4th century BCE, were labeled as dragon bones, while "dragon bones" were prescribed for ailments from madness to diarrhea. There’s no evidence as to the effectiveness of this treatment, however.

In 1822, Mary Ann Mantell was accompanying her husband, obstetrician, and paleontologist Gideon Mantell, on a visit to a patient in Sussex, England, when she noticed something at the side of the road. Looking closer, she found large teeth embedded into the rock.

Her husband Gideon realized that the fossil belonged to a creature unknown to science. He continued to study it and later named it Iguanadon after its iguana-like teeth. Later, paleontologist Richard Owen examined a number of fossil sets and concluded that Iguanodon, Megalosaurus, and Hylaeosaurus fossils were from "a distinct tribe or sub-order of Saurian Reptiles" which he termed, "dinosauria". (2)

Earth Science

Today, an entire field of science is dedicated to the study of the earth, aptly named Earth Science. It includes four branches of study, including geology, meterology, oceanography and astronomy. Geologists specializing in the earth’s history are palentologists, and this group studies fossils to gather evidence to piece together what the ancient past might have been like.

Norman Ross of the division of Paleontology, National Museum, preparing the skeleton of a baby dinosaur some seven or eight million years old for exhibition. , 1921.

It’s getting harder and harder to access places where fossils are plentiful and the Earth Sciences Foundation, Inc. (ESF) was founded to help locate and protect fossils before they disappear. The foundation’s goal is to get people excited about and involved in earth sciences. Fields of study include everything from paleontology, to GIS to surveying.

One of the biggest issues facing scientists is keeping track of fossils, both in the ground and after they have been shipped to museums or universities for study. Recent headlines attest to the difficulty museums face in keeping track of all of their artifacts. Fortunately, there is an elegant solution to this pervasive (and costly) problem.

Each fossil was identified with a unique RFID tag that connected it to its record in ArcGIS. Data about the fossil was added throughout the process - accessible to all stakeholders in real time.

Berntsen has been working with The Earth Sciences Foundation to leverage the power of RFID to use GIS to track and manage dinosaur bones. Our InfraMarker Connected RFID has the potential to revolutionize how these precious artifacts are tracked from the time they are excavated until they are put on display in museums or sent to universities across the world for study. A simple RFID tag connected to GIS will allow scientists to see all the data about any specific artifact, including where it was found, photographs, video, notes and any other information about it, simply by accessing GIS. The RFID tag will stay with each artifact throughout its academic journey, making both the information and the location accessible at any time.

Dig to Display: Transforming Dinosaur Bone Asset Management with InfraMarker RFID and GIS

View of bone fossil locations on a map, with the selected bone displaying its data.

A recently-published study describes how dinosaur bones at Standing Rock Sioux lands in South Dakota were tracked from dig to display. ESF staffers used ArcGIS, Survey123 and InfraMarker RFID to track 347 artifacts from excavation to storage to display.

The bone tracking and management process is simple. Each discovered fossil was ‘tagged’ in the field with a tiny HID RFID marker to establish a unique digital and physical ID. That ID, and contemporaneous information, was captured by a field tech using a tablet with data collection software connected to a GIS platform. RFID scans of the bone’s tag tracked the bone as it moved through various zones from field to storage to cleaning to display, adding data to its GIS record. Simultaneously, hundreds of miles from the dig site, the contractor’s GIS platform displayed a map of original and current bone location and status as it moved from field to institute. Throughout the process, all RFID interrogation data was collected in the cloud, providing near real-time visibility of bone status by auditors hundreds of miles from the dig site.

One of the RFID tags used in the study.

Saves time; near perfect accuracy

Study results found a reduction of field data collection time by 80 percent, nearly perfect tracking of bones through the cycle from field to museum, and enabled easy data sharing and auditing of field work by related organizations.

The study demonstrated the benefits of the RFID/GIS integration that are making a huge difference in many industries - from utility management to agriculture, forestry and manufacturing. Another recent study shows how RFID can help identify and verify underground utilities, streamlining utility management and enhancing safety.

RFID and GIS - Accuracy, versatility and power

RFID and GIS expanding the benefits of location intelligence to new applications and streamlining access to valuable assets - from buried utilities to museum artifacts. Sales of RFID and GIS are exponentially growing because of the tremendous advantages these technologies offer across industries. When RFID is integrated with GIS through InfraMarker, accurate asset management is enabled by connecting the physical asset to its digital files that can be quickly accessed on-site with a simple RFID scan (or even a NFC scan from a cell phone). RFID provides asset authentication at the site of any asset, streamlining field work and improving accuracy and automatically generating tracking information. Any organization that needs to track and manage assets across space and time will benefit from incorporating InfraMarker RFID with their GIS.

Berntsen Adds NFC capability to the InfraMarker RFID App

Berntsen International, a leading manufacturer of infrastructure marking products, announces that its InfraMarker RFID App now supports Near Field Communication (NFC) and is available on both the Apple App Store and Google Play.

Berntsen International, a leading manufacturer of infrastructure marking products, announces that its InfraMarker RFID App now supports Near Field Communication (NFC) and is available on both the Apple App Store and Google Play.

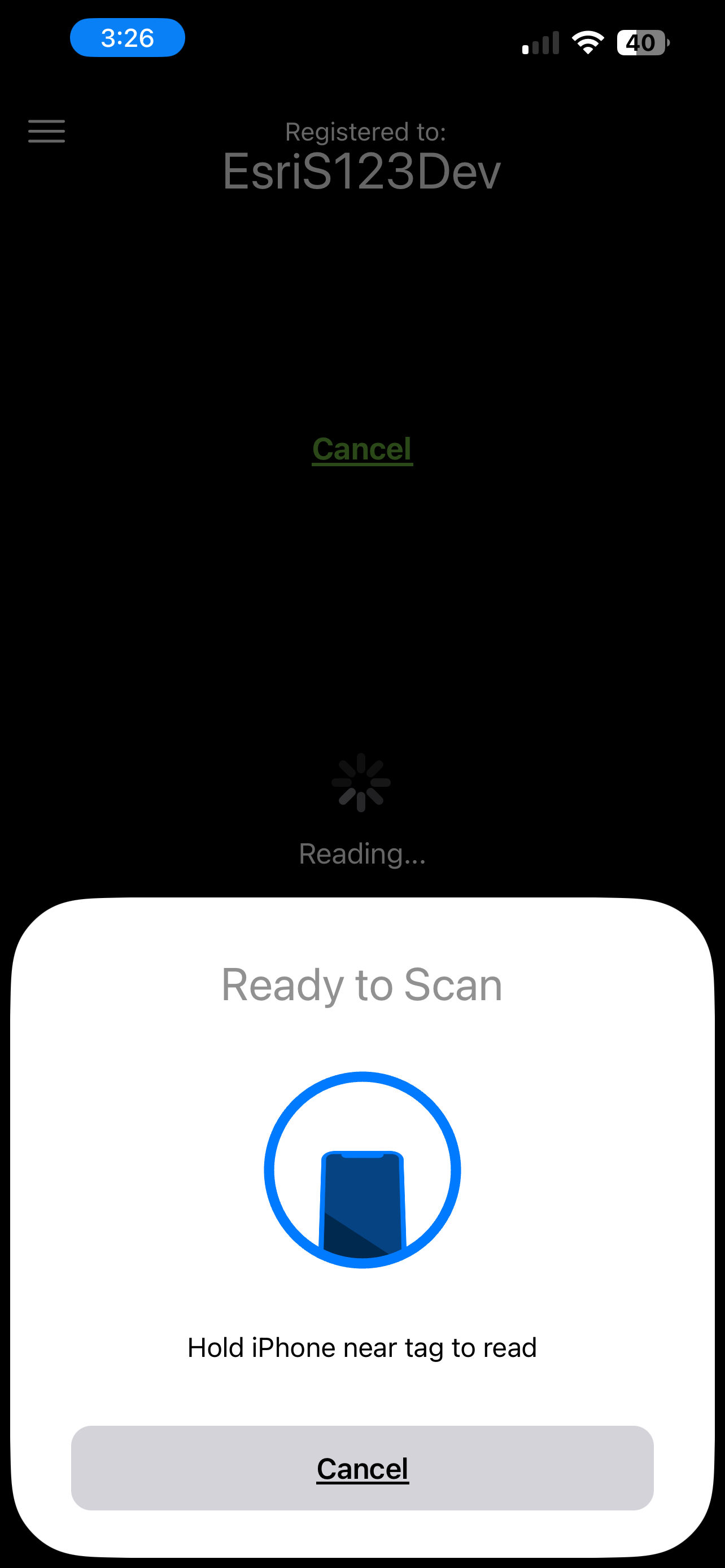

Screenshot of the InfraMarker app ready to scan via NFC

The InfraMarker RFID app improves asset management by connecting UHF (Ultra-high frequency) RFID asset identification tags with the ESRI’s ArcGIS platform. Berntsen has expanded InfraMarker by integrating NFC identification tags with the ESRI platform. With InfraMarker, a simple RFID or NFC scan can trigger the power of GIS and bring data, inspection forms, or maintenance records to the field for fast, reliable asset management.

Any smart phone equipped with the ability to make contactless card payments via NFC will support the InfraMarker NFC App. The InfraMarker NFC app augments the phone’s capability to include access to passive UHF RFID chips at close range – under four inches (10 centimeters).

RFID is the fastest growing asset identification technology in the world thanks to its ruggedness, affordability, and ability to provide a unique serial number for any type of product. Berntsen is the leader in linking RFID technology to the digital management systems used by utilities, public works, and construction.

“We are proud to add NFC to the InfraMarker field app. This dramatically expands the number of assets that can be marked and managed using RFID for utilities, public works, and construction firms.” said Mike Klonsinski, president of Berntsen.

InfraMarker, a division of Berntsen International, is the leader in connected RFID-enabled infrastructure asset marking products and software. The InfraMarker line includes rugged RFID-enabled marking products, RFID readers and accessories, and RFID-connecting software to enhance GIS and asset management platforms.

About Berntsen International, Inc.

Since 1972, Berntsen International has provided high quality marking products to define the boundaries and infrastructure of the world. Berntsen marking products have been deployed throughout the world and its survey caps and monuments are recognized as the global standard.

Berntsen’s commitment to better infrastructure marking is taken to the next level with its innovative InfraMarker line of software, products, and solutions. The InfraMarker approach enables a connected infrastructure world by linking GIS platforms with RFID asset marking technology. Connected RFID infrastructure improves safety and field operations management for utilities, municipalities, and other organizations desiring better field asset management.

Excavating the 2022 DIRT Report

The amount of utility installation and improvement set to occur across the U.S. over the next several years will result in an enormous increase in excavation activity. That means a boom for local economies–and a boom in the number of excavation damages, according to the latest Damage Information Reporting Tool (DIRT Report) from the Common Ground Alliance (CGA).

The amount of utility installation and improvement set to occur across the U.S. over the next several years will result in an enormous increase in excavation activity. That means a boom for local economies – and a boom in the number of excavation damages, according to the latest Damage Information Reporting Tool (DIRT Report) from the Common Ground Alliance (CGA).

The CGA is a member-driven association of more than 3,200 damage prevention professionals in every facet of the underground utility industry. It includes organizations in the North American utility sector, from gas transmission companies to telecom to rail, state regulators, public works, utility locators and more.

The 2020 DIRT Report found concerning increases across key damage indicators. Damage to underground utilities, which pose severe risks to public safety and interrupt commerce, has trended upward over the last three years. Three-year modeling from 2020-2022 reveals that damage per construction spending rose 12.35% and damages per 1,000 transmissions rose 9.34% between 2021 and 2022. The report analyzed all 2022 data submitted voluntarily to DIRT by facility operators, utility locating companies, 811 centers, contractors, regulators and others from the U.S. and Canada.[1]

The report revealed that 76% of all damages in 144,531 submitted reports are due to just six root causes, the same culprits that make the top six year after year. Of those, the top three are:

No notification made to 811 Center (24.81%) 35,860 reports

Facility not marked due to locator error (15.19%) 21,951 reports

Excavator failed to maintain clearance after verifying marks (13.46%) 19,448 reports [2]

It’s obvious that eliminating these root causes simply requires following recommended, common-sense procedures. Excavation occurs for all kinds of reasons in diverse settings by professional and non-professionals, so getting everyone to follow a set procedure is easier said than done. State 811 call centers do a good job of letting homeowners know to call before digging, so the focus of CGA is to get industry partners to work toward damage reduction.

This year’s DIRT Report underscores the urgent need for GIS-based mapping of assets and better communication between stakeholders. This not only promotes safety, but it also improves locating times and increases accuracy. [3]

A long-time member of CGA, Berntsen has merged its expertise in underground marking with GIS and RFID, creating a simple approach to locating and verifying assets of all kinds, above and below ground. InfraMarker Connected RFID was specifically developed to address the issues organizations face during excavation by providing precise verification of each marked asset, then automatically connecting that asset to its GIS record using a mobile device. That means that field staff can identify marked assets below ground and access records that include photo, video, schematics and maintenance records of any asset – before ground is broken. Additionally, this information is shareable between and within organizations, addressing the communication issues that plague any project.

The results of a seven-year longitudinal study that evaluated the functionality, durability and user-friendliness of InfraMarker Connected RFID were recently published. In 2015, a range of buried utilities (gas, water, electric, telecom and other assets) were marked in a residential/commercial area. Over the next seven years, the RFID tags that marked the utilities were accessed using an RFID scanner connected to mobile devices running InfraMarker apps and GIS.

The study demonstrated that InfraMarker RFID functions as intended (quickly identifying underground utilities and linking each asset to its record in GIS), and continues to function as intended over time. Rugged markers buried with or near underground utilities were accessed, read and quickly updated in GIS. InfraMarker RFID literally ties the physical asset to its data in GIS, providing vital information about buried assets to excavators and utility owners. That means fewer utility strikes, improved safety, and fewer construction delays.

The CGA states “Our ability to advance as an industry depends on our willingness to adapt legacy processes to the demands of modern-day damage prevention. The opportunity exists to create meaningful change, but only if we meet this moment with the necessary urgency.”

It is possible. InfraMarker Connected RFID is key to elevating the value of GIS from a digital map to a repeatable way physically verify the identity of each buried asset over time.

The 2022 DIRT Report concludes:

Now is the time for the damage prevention industry to take decisive, bold action by embracing innovation, capitalizing on technological advancements and working together to reimagine a damage prevention process that works for all stakeholders.[4]

References:

[2] Common Ground Alliance DIRT Annual Report 2022 - FINAL (1).pdf page 14

[3] Common Ground Alliance DIRT Annual Report 2022 - FINAL (1).pdf page 1

[4] Sarah K. Magruder Lyle, President & CEO Common Ground Alliance, Common Gound Alliance 2022 DIRT Report 2

Public Works — Key to civilization

Public works have been around ever since people found ways to ensure a reliable source of water for their crops. In 4000 BC, the ancient Sumerians created a successful irrigation system that watered fields between the Tigris and Euphrates Rivers.

What does the term “Public Works” mean? It’s one of those terms that are so broad that it almost defies definition.

The American Public Works Association (APWA) says “Because of the multi-faceted, ever-evolving nature of public works, we may never arrive at a final definition but, for now, the following definition seems appropriate: Public works is the combination of physical assets, management practices, policies, and personnel necessary for government to provide and sustain structures and services essential to the welfare and acceptable quality of life for its citizens.”

A Long History

By Saqib Qayyum - Own work, CC BY-SA 3.0,

A 2.4m deep, 12m long, and 7m wide pool known as "The Great Bath" is located at the centre of the Citadel, is made of fine baked waterproof mud bricks and a thick layer of bitumen. It is the earliest public water tank of the ancient world. Adjacent to it are a well that was used to supply water to the bath.

Public works have been around ever since people found ways to ensure a reliable source of water for their crops. In 4000 BC, the ancient Sumerians created a successful irrigation system that watered fields between the Tigris and Euphrates Rivers. In Mohenjo‐Daro, a major urban center of the Indus Civilization (India), a sophisticated system for supplying water and expelling sewage dates back to the mid-third millennium BC. Water came from more than 700 wells and supplied not only domestic demands but also a system of private baths and a Great Bath for public use. Drains and sewers were carefully constructed to facilitate the removal of waste.[1]

Beginning in 586 BC, the Nabataeans, who lived in northern Arabia and the southern Levant, created a sophisticated water collection system which allowed them to build an impressive trade empire in the heart of arid Arabia.[2]

Of course, everyone knows about the Romans, who constructed roads, harbor works, aqueducts, temples, forums, town halls, arenas, baths, and sewers – many of which are still seen today, more than 2,000 years later. These public works were designed to stabilize and strengthen the empire and make the lives of Roman citizens better.

Recent history

Fast forward a couple thousand years, and public works became key to stabilizing the American economy during a time of crisis. Back in 1933, the federal government undertook a massive public works effort to counteract the devastating effects of the Great Depression. For a decade, the federal government poured $3.8 billion through the Public Works Administration (PWA) into projects that radically transformed the country’s infrastructure. Prominent projects included New York’s Triborough Bridge, Grand Coulee Dam, the San Francisco Mint, Reagan National Airport and Key West’s Overseas Highway.[3]

Later, in 1935, President Roosevelt used an executive order to create the Works Progress Administration (WPA). At the time, unemployment was holding steady at 20 percent, and the economy needed a serious boost. The WPA employed mostly unskilled men to carry out public works infrastructure projects. They built more than 4,000 new school buildings, erected 130 new hospitals, laid roughly 9,000 miles of storm drains and sewer lines, built 29,000 new bridges, constructed 150 new airfields, paved or repaired 280,000 miles of roads and planted 24 million trees to alleviate loss of topsoil during the Dust Bowl. Over the course of 10 years, the WPA put 8.5 million people to work, strengthening communities and laying the groundwork for the largest industrial expansion in history -- the wartime economy of 1945.

The Infrastructure Investment and Jobs Act

Today, the country is in the midst of another massive public works investment. The Infrastructure Investment and Jobs Act (IIJA) was signed into law on November 15, 2021. The IIJA is an historic investment in our nation’s infrastructure: $1.2 trillion over five years, including $550 billion in new federal spending, including --

passenger and freight rail;

highway and pedestrian safety;

public transit;

broadband;

ports and waterways;

airports;

water infrastructure;

power and grid reliability and resiliency;

resiliency, including funding for coastal resiliency, ecosystem restoration, and weatherization;

clean school buses and ferries;

electric vehicle charging;

addressing legacy pollution by cleaning up Brownfield and Superfund sites and reclaiming abandoned mines; and

Western Water Infrastructure[4]

The American Public Works Association (APWA)

The APWA is an organization that was founded to help public works professionals improve their skills, share information and work together to find the best ways to help their communities. Along with comprehensive training programs and other resources, the APWA helps its members learn about and apply for funds provided by the Infrastructure Investment and Jobs Act.

Each year, the APWA organizes a conference and exposition to help keep its members informed. This year’s conference, held in San Diego, includes 125 technical and professional development sessions using the latest learning models: classroom, interactive, and "live" learning labs. Additionally, more than 400 companies will be exhibiting the latest technology – including Berntsen International’s InfraMarker Connected RFID in booth 1939.

InfraMarker is key to smooth operations

Today, public works is more complex than ever. Even in small cities, more and more organizations are relying on the power of GIS to help manage their assets and streamline operations. InfraMarker RFID is designed to leverage the power of GIS to accurately mark and manage any type of asset - directly from the asset point itself. Each passive RFID marker identifies the asset, connecting to GIS with a simple scan, providing verified asset identity and launching the the associated workflow. This instant asset confirmation of ]identity removes guess-work from field maintenance and speeds routine inspection and maintenance with accurate documentation.

We invite all public works professionals who manage infrastructure assets to see how InfraMarker RFID can improve asset management by providing verified field asset information that links to any GIS system. Sign up here to chat with Brent Sherman, our Sales Manager for a live demo of how InfraMarker can work for you at the APWA Conference, booth 1939, August 27-29.

See how it works:

References:

[2] https://www.ancient-origins.net/artifacts-ancient-technology/nabateans-002193

[3] https://livingnewdeal.org/glossary/public-works-administration-pwa-1933-1943/

Sources:

https://livingnewdeal.org/glossary/public-works-administration-pwa-1933-1943/

http://www.waterencyclopedia.com/Tw-Z/Water-works-Ancient.html#ixzz89u0Sv4uO

It’s National 811 Day —

811 Day was created to bring attention to a significant but little-known issue – the high cost and safety impacts of underground utility strikes.

Quantifying the cost and safety impacts of utility strikes is difficult. A compilation of various studies estimates that the direct cost of each strike is $4,000 -- but that doesn’t take into consideration the cost to repair and restore the damage.

Little-known but incredibly important

811 Day was created to bring attention to a significant but unfamiliar issue – the high cost and safety impacts of underground utility strikes.

Quantifying the cost and safety impacts of utility strikes is difficult. A compilation of various studies estimates that the direct cost of each strike is $4,000 -- but that doesn’t take into consideration the cost to repair and restore the damage. Taken together, the cost of the strike plus the cost of restoration, the total is 29 times the cost of the direct damage itself [1]. Because utility strikes are often not reported, the frequency of occurrence is merely an estimate. With more than 20 million miles of buried pipelines, cables, wires and other facilities, the Common Ground Alliance (CGA) estimates that there are at least 400,000 utility strikes per year in the United States. In 2021, the cost of utility strikes to the US economy was estimated to be more than $30 billion.

Utility strikes have been a problem for a long time – ever since the 1850s when the first underground sewer systems were built in Chicago and Brooklyn.

Act of Congress

It wasn’t until 1994 that the government got involved. At that time, Congress required each state to develop a One-Call system with a centralized number to call in advance of digging. The goal of the one-call system is simplicity. Any person or company planning to excavate can call an in-state number and the utility companies would be notified to send a Utility Locator to find and mark utilities using spray paint and/or flags. Unfortunately, the number of One-Call Centers quickly grew to 71, each with its own 10-digit phone number, making it confusing and taxing to notify the right people before breaking ground.

In response, in 1995, the FCC designated 811 as the nationwide number to call (or click) to protect pipelines and other utilities from excavation damage.

Today, 811 is contacted nearly 40 million times annually [2].

Despite the fact that use of 811 one-call centers rose by eight percent from 2020 to 2021, “No notification made to 811 center” remains the top root cause of utility strikes with over a quarter of all damages still attributed to no notification)[3].

Much more to be done

Although it’s simpler than ever to call for utility location, utility strikes remain a major drag on the American economy. Fortunately, emerging technology is being used to produce precise maps of underground utilities that speed the process of identifying and locating underground utilities.

For example, Geographic Information Systems (GIS), are being used by growing numbers of utilities, municipalities and excavators to create and share data about underground utilities. Unfortunately, having an accurate map of all utilities in a given area is rare, because not every contractor or owner working on a job site uses GIS to map utilities. That’s when another technology, Radio Frequency Identification (RFID), can make all the difference. Magnetic RFID tags can be buried with any type of utility and will display its identity, owner and other information with a simple scan. This data can be incorporated into GIS (such as Esri’s ArcGIS) through data collection apps on mobile devices. RFID is agnostic, so it will work with any utility, above or below ground.

RFID and GIS are key

Passive RFID tags don’t require power (they activate only when scanned) so they can last underground for years. A recently released study describes how RFID has been used to mark and manage utilities over a period of seven years. The study concluded that magnetic RFID marking, coupled with GIS mapping, is a low-cost, reliable solution for underground infrastructure locating and management.

Marking underground utilities with magnetic RFID is a long-term solution that streamlines future utility locating processes while providing the means to connect to digital mapping systems for efficient utility management -- from water pipes to fiber-optic cables. Utility location verified by RFID, provides a highly accurate method for utility owners to manage all of their infrastructure facilities.

Today, on 8/11 calling 811 remains essential part any excavation, from individuals working in their backyards to construction companies about to break ground on a new project.

References:

[3] https://dirt.commongroundalliance.com/2021-DIRT-Report/Executive-Summary#mainContentAnchor

Sources:

https://www.4manalytics.com/blog/29-1-the-cost-of-striking

The 811 Logo is a registered trademark of the Common Ground Alliance

InfraMarker Brings RFID Power to Esri Field Operation Applications

Berntsen International, a leading manufacturer of infrastructure marking products, announces that its InfraMarker RFID app is now fully integrated with Esri’s ArcGIS Survey123 and ArcGIS Field Maps mobile applications.

MADISON, Wisc., July 3, 2023 - Berntsen International, a leading manufacturer of infrastructure marking products, announces that its InfraMarker RFID app is now fully integrated with Esri’s ArcGIS Survey123 and ArcGIS Field Maps mobile applications.

Berntsen’s InfraMarker app connects passive UHF RFID – the fastest growing asset identification technology in the world, with Esri’s ArcGIS, the global market leader in geographic information system (GIS) software. The InfraMarker app enhances Esri’s field data collection tools with the ability to read RFID tag information, write data to a RFID tag, associate the RFID serial number with the asset record in the GIS database, and launch inspection and management forms with a RFID interrogation.

“We are proud to bring RFID – the serial number of IoT – to Esri customers across the globe. We are confident that infrastructure managers in utilities, public works, and construction will realize speed, reliability, and cost benefits with InfraMarker RFID,” said Mike Klonsinski, president of Berntsen.

InfraMarker, a division of Berntsen International, is the leader in connected RFID-enabled infrastructure asset marking products and software. The InfraMarker line includes rugged RFID-enabled marking products, RFID readers and accessories, and RFID-connecting software to enhance GIS and asset management platforms.

About Berntsen International, Inc.

Since 1972, Berntsen International has provided high quality marking products to define the boundaries and infrastructure of the world. Berntsen marking products have been deployed throughout the world and its survey caps and monuments are recognized as the global standard.

Berntsen’s commitment to better infrastructure marking is taken to the next level with its innovative InfraMarker line of software, products, and solutions. The InfraMarker approach enables a connected infrastructure world by linking GIS platforms with RFID asset marking technology. Connected RFID infrastructure improves safety and field operations management for utilities, municipalities, and other organizations desiring better field asset management.

Berntsen is a Silver Partner in the Esri Partner Network, and InfraMarker RFID is an approved ArcGIS System Ready Specialty accessible on Esri's ArcGIS Marketplace. Visit Inframarker.com for more information and to purchase an introductory InfraMarker RFID package.

GIS + RFID = SUE Enhancement

Subsurface Utility Engineering (SUE) that leverages Geographic Information Systems (GIS) and Radio Frequency Identification (RFID) deliver substantial benefits in the management and protection of underground assets.

Subsurface Utility Engineering (SUE) that leverages Geographic Information Systems (GIS) and Radio Frequency Identification (RFID) deliver substantial benefits in the management and protection of underground assets.

Both GIS and RFID are rapidly-growing, powerful technologies that are used across a wide spectrum of industries, from manufacturing to agriculture to SUE.

When used together, GIS and RFID deliver accurate, verified information about any type of asset – above or below ground. This is particularly compelling for re-locating buried assets before excavation. It’s essential to know what’s below, and scanning the RFID buried asset tag provides authentication of its data in GIS.

RFID is a simple and durable technology, ideal for pairing with GIS. RFID tags consist of a microchip and antenna. Basic information, such as the asset’s location, identity and owner are written to the tag. When scanned, this data connects to GIS, accessing the correct data and launching maintenance/inspection surveys.

Today, a growing number of agencies and municipalities use Esri’s ArcGIS for Subsurface Utility Engineering. Esri’s popular data collection apps integrate with InfraMarker RFID, making accessible to any organization that uses ArcGIS and Field Maps or Survey123. Recently, Esri announced a June Survey123 update that includes a more seamless integration with InfraMarker RFID.

According to Esri:

“With InfraMarker, a field user can scan a RFID tag and instantly launch the related inspection form in Survey123 … faster and without errors in asset misidentification. You can also use InfraMarker for Survey123 to write information to a new RFID tag and easily associate the unique identifier in your ArcGIS system of record.

The technology is increasingly used in infrastructure asset management thanks to its durability in the field, flexibility to serve as a unique ID on almost any asset, and ability to be read from distance or through mediums such as walls, ground, or concrete.”

SUE and RFID for Infrastructure

This technology is on target for use in all kinds of infrastructure projects that rely on Subsurface Utility Engineering.

The 2022 CGA Technology Report notes that applying emerging mapping/GIS technologies in project design and SUE would reduce potholing and associated expenses involved in locating buried utilities.[1] This report delivers a snapshot of how technology is used specifically to prevent damage during excavation. RFID is included for facility installation and locating, and stated that “a comprehensive national GIS map of buried infrastructure would make the locating process drastically more efficient and accurate, and identify abandoned facilities.”

A recent longitudinal study has demonstrated the long-term feasibility of combining RFID and GIS.

Staking University in Manteno, IL was the site for a perfect test case of using this technology in a residential setting. This campus encompasses more than 20 acres of live and abandoned utilities offering real-world conditions for field testing utility products.

Because RFID markers are passive, they can simply be scanned and connected to GIS for verification – even years later.

In 2015, 174 RFID markers were placed on or near utilities. Utilities marked were:

RFID markers of all utilities displayed in GIS

Gas

Electric

Telecom

Potable Water

Sewer

Periodically, the markers were located again by following a simple process – follow the GIS map to the area of a buried marker, scan it through the ground using the RFID reader (which displays and loads the RFID tag), then update that specific record via the InfraMarker mobile app.

In 2022, a thorough review of every marker was conducted and 93% of 174 buried RFID markers were located after seven years in the ground and 97.5% of those produced a successful RFID read.

This study offers a perfect basis to estimate the cost savings for locating and managing a range of utilities.

The average cost per utility strike is $4,000[2].

Assuming one utility strike per year per utility (5 utilities) x 7 (years), the result is 35 utility strikes.

Multiply that by $4,000 and the cost is $140,000.

The cost of the InfraMarker system (174 tags) $3,480 + software (7 years at $2,500/year = 17,500, making a total investment of $20,980.

$140,000 - $20,980 = 119,020

93% of utilities were located, which means $110,688 in utility strikes were prevented.

InfraMarker installation and one year cost is negligible compared to the potential savings resulting from efficient and accurate management of infrastructure assets. Safety is also enhanced due to more accurate asset locating and identification, preventing costly and dangerous utility strikes.

Additional benefits delivered:

One or more utilities can be managed and tracked within one commonly used GIS platform.

Data can be shared within and between organizations or can be controlled to prevent sharing.

InfraMarker’s cloud provides auditable tracking of an organization’s RFID facility activity.