It’s National 811 Day —

811 Day was created to bring attention to a significant but little-known issue – the high cost and safety impacts of underground utility strikes.

Quantifying the cost and safety impacts of utility strikes is difficult. A compilation of various studies estimates that the direct cost of each strike is $4,000 -- but that doesn’t take into consideration the cost to repair and restore the damage.

Little-known but incredibly important

811 Day was created to bring attention to a significant but unfamiliar issue – the high cost and safety impacts of underground utility strikes.

Quantifying the cost and safety impacts of utility strikes is difficult. A compilation of various studies estimates that the direct cost of each strike is $4,000 -- but that doesn’t take into consideration the cost to repair and restore the damage. Taken together, the cost of the strike plus the cost of restoration, the total is 29 times the cost of the direct damage itself [1]. Because utility strikes are often not reported, the frequency of occurrence is merely an estimate. With more than 20 million miles of buried pipelines, cables, wires and other facilities, the Common Ground Alliance (CGA) estimates that there are at least 400,000 utility strikes per year in the United States. In 2021, the cost of utility strikes to the US economy was estimated to be more than $30 billion.

Utility strikes have been a problem for a long time – ever since the 1850s when the first underground sewer systems were built in Chicago and Brooklyn.

Act of Congress

It wasn’t until 1994 that the government got involved. At that time, Congress required each state to develop a One-Call system with a centralized number to call in advance of digging. The goal of the one-call system is simplicity. Any person or company planning to excavate can call an in-state number and the utility companies would be notified to send a Utility Locator to find and mark utilities using spray paint and/or flags. Unfortunately, the number of One-Call Centers quickly grew to 71, each with its own 10-digit phone number, making it confusing and taxing to notify the right people before breaking ground.

In response, in 1995, the FCC designated 811 as the nationwide number to call (or click) to protect pipelines and other utilities from excavation damage.

Today, 811 is contacted nearly 40 million times annually [2].

Despite the fact that use of 811 one-call centers rose by eight percent from 2020 to 2021, “No notification made to 811 center” remains the top root cause of utility strikes with over a quarter of all damages still attributed to no notification)[3].

Much more to be done

Although it’s simpler than ever to call for utility location, utility strikes remain a major drag on the American economy. Fortunately, emerging technology is being used to produce precise maps of underground utilities that speed the process of identifying and locating underground utilities.

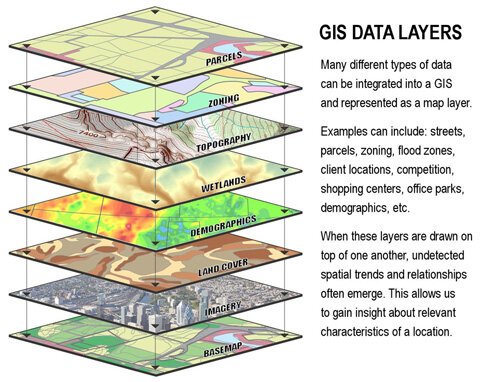

For example, Geographic Information Systems (GIS), are being used by growing numbers of utilities, municipalities and excavators to create and share data about underground utilities. Unfortunately, having an accurate map of all utilities in a given area is rare, because not every contractor or owner working on a job site uses GIS to map utilities. That’s when another technology, Radio Frequency Identification (RFID), can make all the difference. Magnetic RFID tags can be buried with any type of utility and will display its identity, owner and other information with a simple scan. This data can be incorporated into GIS (such as Esri’s ArcGIS) through data collection apps on mobile devices. RFID is agnostic, so it will work with any utility, above or below ground.

RFID and GIS are key

Passive RFID tags don’t require power (they activate only when scanned) so they can last underground for years. A recently released study describes how RFID has been used to mark and manage utilities over a period of seven years. The study concluded that magnetic RFID marking, coupled with GIS mapping, is a low-cost, reliable solution for underground infrastructure locating and management.

Marking underground utilities with magnetic RFID is a long-term solution that streamlines future utility locating processes while providing the means to connect to digital mapping systems for efficient utility management -- from water pipes to fiber-optic cables. Utility location verified by RFID, provides a highly accurate method for utility owners to manage all of their infrastructure facilities.

Today, on 8/11 calling 811 remains essential part any excavation, from individuals working in their backyards to construction companies about to break ground on a new project.

References:

[3] https://dirt.commongroundalliance.com/2021-DIRT-Report/Executive-Summary#mainContentAnchor

Sources:

https://www.4manalytics.com/blog/29-1-the-cost-of-striking

The 811 Logo is a registered trademark of the Common Ground Alliance

GIS + RFID = SUE Enhancement

Subsurface Utility Engineering (SUE) that leverages Geographic Information Systems (GIS) and Radio Frequency Identification (RFID) deliver substantial benefits in the management and protection of underground assets.

Subsurface Utility Engineering (SUE) that leverages Geographic Information Systems (GIS) and Radio Frequency Identification (RFID) deliver substantial benefits in the management and protection of underground assets.

Both GIS and RFID are rapidly-growing, powerful technologies that are used across a wide spectrum of industries, from manufacturing to agriculture to SUE.

When used together, GIS and RFID deliver accurate, verified information about any type of asset – above or below ground. This is particularly compelling for re-locating buried assets before excavation. It’s essential to know what’s below, and scanning the RFID buried asset tag provides authentication of its data in GIS.

RFID is a simple and durable technology, ideal for pairing with GIS. RFID tags consist of a microchip and antenna. Basic information, such as the asset’s location, identity and owner are written to the tag. When scanned, this data connects to GIS, accessing the correct data and launching maintenance/inspection surveys.

Today, a growing number of agencies and municipalities use Esri’s ArcGIS for Subsurface Utility Engineering. Esri’s popular data collection apps integrate with InfraMarker RFID, making accessible to any organization that uses ArcGIS and Field Maps or Survey123. Recently, Esri announced a June Survey123 update that includes a more seamless integration with InfraMarker RFID.

According to Esri:

“With InfraMarker, a field user can scan a RFID tag and instantly launch the related inspection form in Survey123 … faster and without errors in asset misidentification. You can also use InfraMarker for Survey123 to write information to a new RFID tag and easily associate the unique identifier in your ArcGIS system of record.

The technology is increasingly used in infrastructure asset management thanks to its durability in the field, flexibility to serve as a unique ID on almost any asset, and ability to be read from distance or through mediums such as walls, ground, or concrete.”

SUE and RFID for Infrastructure

This technology is on target for use in all kinds of infrastructure projects that rely on Subsurface Utility Engineering.

The 2022 CGA Technology Report notes that applying emerging mapping/GIS technologies in project design and SUE would reduce potholing and associated expenses involved in locating buried utilities.[1] This report delivers a snapshot of how technology is used specifically to prevent damage during excavation. RFID is included for facility installation and locating, and stated that “a comprehensive national GIS map of buried infrastructure would make the locating process drastically more efficient and accurate, and identify abandoned facilities.”

A recent longitudinal study has demonstrated the long-term feasibility of combining RFID and GIS.

Staking University in Manteno, IL was the site for a perfect test case of using this technology in a residential setting. This campus encompasses more than 20 acres of live and abandoned utilities offering real-world conditions for field testing utility products.

Because RFID markers are passive, they can simply be scanned and connected to GIS for verification – even years later.

In 2015, 174 RFID markers were placed on or near utilities. Utilities marked were:

RFID markers of all utilities displayed in GIS

Gas

Electric

Telecom

Potable Water

Sewer

Periodically, the markers were located again by following a simple process – follow the GIS map to the area of a buried marker, scan it through the ground using the RFID reader (which displays and loads the RFID tag), then update that specific record via the InfraMarker mobile app.

In 2022, a thorough review of every marker was conducted and 93% of 174 buried RFID markers were located after seven years in the ground and 97.5% of those produced a successful RFID read.

This study offers a perfect basis to estimate the cost savings for locating and managing a range of utilities.

The average cost per utility strike is $4,000[2].

Assuming one utility strike per year per utility (5 utilities) x 7 (years), the result is 35 utility strikes.

Multiply that by $4,000 and the cost is $140,000.

The cost of the InfraMarker system (174 tags) $3,480 + software (7 years at $2,500/year = 17,500, making a total investment of $20,980.

$140,000 - $20,980 = 119,020

93% of utilities were located, which means $110,688 in utility strikes were prevented.

InfraMarker installation and one year cost is negligible compared to the potential savings resulting from efficient and accurate management of infrastructure assets. Safety is also enhanced due to more accurate asset locating and identification, preventing costly and dangerous utility strikes.

Additional benefits delivered:

One or more utilities can be managed and tracked within one commonly used GIS platform.

Data can be shared within and between organizations or can be controlled to prevent sharing.

InfraMarker’s cloud provides auditable tracking of an organization’s RFID facility activity.

Long-lasting solution - Passive RFID markers continue to connect to software over time, no matter how that software is modified and improved. More and more data can be added to each point, including video, sketches, photos and files – whatever information each organization requires.

Summary

The Common Ground Alliance[3] states that each year, $30 billion in costs are associated with utility strikes. Increased construction spending has consistently proven to correlate with an increase in damage. Anticipated funding from the Infrastructure Investment and Jobs Act is predicted to stress an already inundated damage prevention system[4].

Using RFID/GIS in conjunction with Subsurface Utility Engineering (SUE) amplifies savings and efficiency. The results of a range of DOT studies show that for every dollar spent on SUE, $11.39 in savings are generated[5] by avoiding expensive construction delays and costly utility strikes. Now is the time to create a lasting, accurate picture of subsurface infrastructure that can continue to deliver savings and safety now and in the future.

References:

[1] Technology Advancements & Gaps in Underground Safety Volume 5. © 2022 Common Ground Alliance

[4] DIRT Annual Report for 2021 © 2022 Common Ground Alliance

INVESTMENTS IN SUBSURFACE UTILITY MAPPING TECHNOLOGY MEAN BIG SAVINGS FOR CITIES

Construction intended to improve public infrastructure is the most costly and involved public works undertakings by government and contracting firms.

It’s surprising that many of the costs associated with large-scale construction projects stem from either relocating underground utilities or simply designing around them so they don’t need to be moved.

Construction intended to improve public infrastructure is the most costly and involved public works undertakings by government and contracting firms.

It’s surprising that many of the costs associated with large-scale construction projects stem from either relocating underground utilities or simply designing around them so they don’t need to be moved.

These costs could be avoided if accurate information about the nature and location of underground utilities were available. Unfortunately, accurate data is not available. In many cases missing or inaccurate buried infrastructure information increases the risk of cost and schedule overruns – compounding the expense of major projects.

This lack of buried asset information is estimated to cost the U.S. about $50 billion annually. Traditional mapping and marking techniques simply don’t provide the accuracy required for large scale construction projects.

THIS LACK OF BURIED ASSET INFORMATION IS ESTIMATED TO COST THE U.S. ABOUT $50 BILLION ANNUALLY.

Traditional mapping and marking techniques simply don’t provide the accuracy required for large scale construction projects.

THIS LACK OF BURIED ASSET INFORMATION IS ESTIMATED TO COST THE U.S. ABOUT $50 BILLION ANNUALLY.

Studies show that better mapping systems translate to significant savings

According to a 1999 Purdue University survey sponsored by the US Department of Transportation, a total of $4.62 was saved for every $1.00 spent when comprehensive underground utility location maps informed construction projects.

A 2004 study by the Ontario Sewer and Water main Contractors Association and the University of Toronto found that the average rate of return on every dollar spent to improve the visibility of subsurface utilities resulted in a savings of $3.41.

In 2010 study by the University of Toronto monitored nice large city and highway rebuilding projects found that accurate underground utility marking benefitted every project. Further, a positive ROI on $2.05 to $6.59 resulted from every dollar spent to improve underground utility mapping.

RFID is a cost-saving alternative

Today, many public works departments utilize GIS that can display the location of underground utilities. However, even with GIS-based asset management systems, precision may be difficult to come by. Most systems rely on GPS to find locations, which is only accurate within several feet – not good enough when locating underground gas lines, for instance.

The best way to accurately find underground assets is to physically mark them – then find those markers before construction begins. Fortunately, a combination of proven, reliable technology is now available to streamline this process.

The InfraMarker® RFID-enabled asset management system leverages the unique marking ability of RFID connected to a mobile app that can quickly append data to each specific RFID marker. This data is connected to the GIS and provides a detailed, accurate map of each underground asset – information that can be audited, updated and tracked in the GIS.

Each RFID-enabled marker is rugged, unique and passive which means that it can last as long as the infrastructure and will continue to provide specific asset information each time it is read.

This system provides the accuracy, location verification and comprehensive data that utilities can rely on for accurately mapping and managing both subsurface and above-ground infrastructure assets.

Just contact us to set up a demo to see how the simple, easy-to-use and setup InfraMarker system can save time, money and provide the data you need with the accuracy you require.

RFID Expedites Recovery

Disasters run the gamut, from environmental factors to cyber-threats to aging infrastructure. Keep in mind America receives an overall grade of D+ on the American Society of Civil Engineers Infrastructure Report Card, with the categories of drinking water, energy, and wastewater receiving a D or D+ mark.

Disasters Underscore Critical Need for Connected Utility Infrastructure

Digital Mapping Expedites Disaster Recovery, Has the Potential to Save Lives

On Sept. 14, 2018, Hurricane Florence slammed into the Carolinas, bringing with her powerful winds, torrential rains and the potential to wreak catastrophic destruction. Though Florence was downgraded to a Category 1 storm as it moved over land, its high winds and rain toppled trees, triggered massive flooding and caused power transformers to explode like fireworks, leaving hundreds of thousands of people without power. More than 40 people have died as a result of the storm and flooding.

A day earlier, 800 miles up the East Coast, another disaster had occurred. Dozens of rapid-fire gas explosions caused 70 home fires and one fatality in what one official described as “Armageddon.” Entire neighborhoods north of Boston were forced to evacuate, and firefighters and crews scrambled to fight the flames and shut off the gas and electricity to the affected areas. The fires were caused when too much natural gas was pumped into a section of pipe and then leaked into homes.

These disasters—and others including the California wildfires and Hurricanes Harvey and Irma—are a cogent reminder of the critical need to upgrade and digitize our utility infrastructure. This is especially relevant for all of us at Berntsen who live and work in Wisconsin, where a massive explosion destroyed a city block in downtown Sun Prairie and killed a volunteer firefighter in July. The fact that we design equipment that might have prevented this disaster and so many others saddens us, and this tragedy has deeply affected our employees.

Disasters on the Rise

Disasters run the gamut, from environmental factors to cyber-threats to aging infrastructure. Keep in mind America receives an overall grade of D+ on the American Society of Civil Engineers Infrastructure Report Card, with the categories of drinking water, energy, and wastewater receiving a D or D+ mark.

A 2017 report prepared by Johns Hopkins University notes that the U.S. insurance industry has identified a $20 to $55 billion annual financial loss from power outages caused by flooding, hurricanes, and extreme temperatures. A combination of “higher average global temperatures, more destructive storms, and hurricanes, and increased risk of wildfire will ultimately worsen risk exposure for utilities,” the report states.

Many public and private utilities have state-of-the-art asset management systems to tackle the challenge of disasters, but the widespread deployment of these systems is lacking in much of the country, putting communities and citizens at greater risk. Over time, failure to adopt digital technologies will lead to slower disaster recovery times, potentially greater loss of life and bigger financial losses to business and the public.

“Over time, failure to adopt digital technologies will lead to slower disaster recovery times, potentially greater loss of life and bigger financial losses to business and the public. ”

The good news is digital transformation is coming to the utility industry and innovative technologies already exist to improve disaster planning, response, recovery, and underground asset management.

Connected Marking and Digital Mapping Are a Game Changer

Disasters such as storms, wildfires, explosions, and earthquakes often require gas, water, electric and telecommunications companies to quickly identify, locate and access underground utility assets.

In August 2017, a major fiber network outage in Atlantic Canada shut down cellphone and Internet service, closed some bank branches and delayed flights at multiple airports. The problem was caused when two fiber optics lines were cut during construction work.

The ability to quickly locate and repair underground utility assets is often hampered by outdated maps and inaccurate data. During a disaster, these delays can be devastating and deadly.

Connected marking solutions for utility infrastructure such as the InfraMarker® system from Berntsen International are a game changer for asset management and extremely helpful in disaster recovery. In a disaster, utility crews can use the InfraMarker mobile app and digital mapping software to quickly find the exact location of a gas pipeline shut-off valve to prevent an explosion. It’s that powerful.

This unique combination of RFID, mobile app and digital mapping software significantly expedites underground utility locating.

InfraMarker is a secure and easy way to collect and relay essential utility asset data. From there, the data can be accessed on smartphones and by popular GIS systems such as ArcGIS. Going forward, connected marking solutions will play an integral role in Smart City utility asset management.

In the past, the most important part of infrastructure management was to locate the asset. Today, infrastructure management requirements are greater and more complex. Location and other relevant data need to be available to multiple users faster—ideally in real-time—and to be integrated with GIS, ERP, workflow management and regulatory/compliance systems.

RFID is a highly effective tool for precision locating. But the key advantage of connected marking is the ability to collect, store and share asset data via the cloud. This next-gen innovation delivers exceptional benefits and ROI to utility asset managers, emergency responders, and citizens, and also has the potential to save lives.